المنتجات الساخنة

(PDF) MPS mills for coal grinding ResearchGate

网页2014年1月1日 January 2002 ZKG INTERNATIONAL. H. Gilabert. Since the beginning of 2002, Industrias Rocacem S.A has been operating an MPS 4250 BC roller mill at their Latacunga grinding plant in Ecuador. The

Contact

COAL GRINDING IMPS: more than meets the eye Gebr.

网页2016年12月19日 The MPS coal grinding mill with a high drying capacity is very suitable for grinding lignites with feed moistures of as much as 45 per cent. Depending on this high feed moisture, the mill rating is determined by drying whereas for anthracite, hard coal and petcoke the rating of the mill is determined by grinding. The great

Contact

CFD modeling of MPS coal mill with moisture evaporation

网页2010年5月1日 Today more than 2000 MPS mills are in operation throughout the world [1]. MPS-type pulverizers have a wide range of capacities as well as the ability to dry higher moisture coals [2]. Fig. 1 shows the air and coal flow path inside the mill and several important stages of operation of the MPS mill. Hot primary air enters the throat of the mill

Contact

(PDF) CFD Modeling of MPS Coal Mill for

网页2009年1月1日 Mill performance has a significant impact on combustion performance indicators such as NO x,CO, unburnt carbon, slagging,

Contact

Coal Mills Steam Turbine, Steam Boiler, Power Plant,

网页2010年7月27日 during the past several years to meet these challenging demands. All three (3) types of coal pulverizer systems supplied by RPI originally designed for low, medium and high-speed pulverization have undergone design upgrades and improvements.These machines include Ball Tube Mills (BTM), MPS mills and Atrita® Pulverizers, respectively.

Contact

MPS mills for coal grinding AYS Engineering

网页2021年3月12日 The installed power for the mill main drive is 1300 kW. The specific energy consumption is set at 11.4kWh/t for the main mill drive plus theseparator rotor drive. Delivery time is 12 months, so the mill will be commissioned in late autumn 2014. Commissioning of many coal mills is currently in progress.

Contact

Application of MPS-HP-II Medium-speed Coal Mill in High-moisture Coal

网页To overcome the difficulty in calculating the maximum output and optimizing the operation of a MPS-HP-II medium-speed coal mill,a calculation method was proposed for the new type of mill,and subsequently the calculation results were compared with actual experimental data.Operating conditions suitable for the coal mill were put forward through studies on

Contact

MPS mills for coal grinding Cement Lime Gypsum

网页1 MPS coal grinding mill with SLS high efficiency classifier. 2 Flow sheet. 3 Test center GPSE MPS 32-1. ordered an MPS 6000 B raw mill and an MPS 3350 BK coal mill. The company belonging to the B.K. Birla Group of Companies, which is more. Issue 2013-11 Pfeiffer already supplied four mills of the type more. News.

Contact

ypes of coal mill mps high power grinders mill

网页Abstract and Figures Two mill systems are employed for most coal grinding applications in the cement industry. These are, on the one hand, vertical roller mills (VRM) that have achieved a share of,COAL ON DRY BASIS: 1.ANTHRACITE 2.BITUMINOUS 3.SUB-BITUMINOUS 4.LIGNITE fPULVERISED FORM OF COAL IT HAS MADE MODERN

Contact

Modelling of vertical spindle mills. Part 2: Integrated models

网页2015年3月1日 The sub-models of comminution and classification in VSM operation presented in Part 1 of the stone have been integrated in the VSM simulation models for the E-mill, MPS mill and CKP mill. Plant survey data, including both internal and external stream sampling, were used to calibrate the VSM model parameters.

Contact

Mps Mill PDF Mill (Grinding) Cement Scribd

网页2019年7月24日 GG Gebr. Pfeiffer AG supplies MPS vertical roller mills, ball mills and moleculator mills, separators and kettles to the gypsum industry. The specific power consumption at. the mill drive for grinding natural gypsum ranges from 2.5 to 5.5 kWh/t, which. means it is relatively low, both for grinding-drying and grinding-calcining.

Contact

Reprint from ZKG 3 Gebr. Pfeiffer

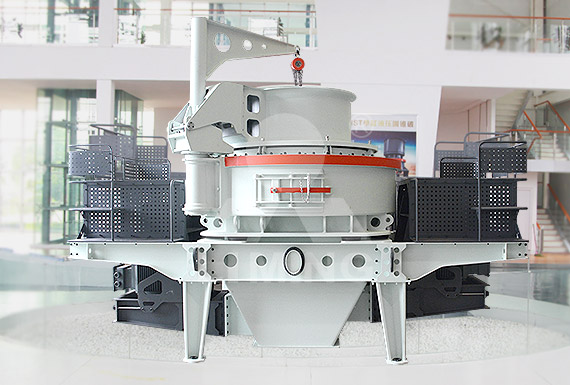

网页2016年12月19日 2 Design features of MPS mills for coal grinding Depending on the material to be ground, through put rates of 5-200 t/h can be achieved in a fine-ness range between 1% R0.063 mm and 25 % R0.090 mm. Thus, the MPS coal grinding mill MPS 3070 BK installed in India PROCESS // Grinding

Contact

Coal Mill an overview ScienceDirect Topics

网页Observer-Based and Regression Model-Based Detection of Emerging Faults in Coal Mills. Peter Fogh Odgaard, Sten Bay Jørgensen, in Fault Detection, Supervision and Safety of Technical Processes 2006, 2007. 5.2 Experiments with and design of the regression model-based approach. Operating data from a coal mill is used to compare the fault detection

Contact

Reprint from ZKG 3 ResearchGate

网页1 MPS coal grinding mill with SLS high-ef ficiency classifier. 4 Reprint from / Sonder druck aus ZKG 3 2014 zkg.de The installed power for the mill main drive is 1300 kW. The specific

Contact

10.1016/j.fuproc.2010.01.002 DeepDyve

网页2020年6月11日 Today more than 2000 MPS mills are in operation throughout the world [1] . MPS-type pulverizers have a wide range of capacities as well as the ability to dry higher moisture coals [2] . Fig. 1 shows the air and coal flow path inside the mill and several important stages of operation of the MPS mill.

Contact

ypes of coal crushing mill

网页Our ATOX Coal Mill is a compact vertical roller mill that can grind almost any type of raw coal The coal mill utilises compression and shear force generated between the large rollers and the rotating table to crush and grind raw coal removing the need for a separate piece of equipment for crushing The coal mill can also grind petroleum coke and

Contact

Modeling of Coal Mill System Used for Fault Simulation

网页2020年4月7日 Monitoring and diagnosis of coal mill systems are critical to the security operation of power plants. The traditional data-driven fault diagnosis methods often result in low fault recognition rate or even misjudgment due to the imbalance between fault data samples and normal data samples. In order to obtain massive fault sample data

Contact

(PDF) MPS mills for coal grinding ResearchGate

网页2014年1月1日 January 2002 ZKG INTERNATIONAL. H. Gilabert. Since the beginning of 2002, Industrias Rocacem S.A has been operating an MPS 4250 BC roller mill at their Latacunga grinding plant in Ecuador. The

Contact

Comparison of energy efficiency between E and MPS type

网页2017年7月1日 For VSP used in coal power plants, the Julius Kruttschnitt Mineral Research Centre (JKMRC) and China University of Mining and Technology (CUMT) conducted industrial sampling experiments on E, MPS and CKP type VSPs in Australia and China, respectively. However, the fineness of PF for the MPS mill is high, with the P 80 at

Contact

coal grinder mps125 ecole-poix-terron.fr

网页In coal fired power plants coal mills are used to pulverize and dry to coal before it is blown into the power plant furnace. The coal is feed into the coal mill through a central inlet pipe where gravity is used to lead the coal to the bottom of the mill where the grinding table and some heavy rollers pulverizes the coal to particles. Nhận giá

Contact

(PDF) CFD Modeling of MPS Coal Mill for Improved

网页2009年1月1日 Mill performance has a significant impact on combustion performance indicators such as NO x,CO, unburnt carbon, slagging, fouling, flame stability and boiler capacity. The MPS-type pulverizer

Contact

Modeling of a medium speed coal mill ScienceDirect

网页2017年8月1日 Brief introduction of a coal mill. MPS-type medium speed coal mills are widely used in the thermal power plants in China. They are designed and manufactured by the German company Babcock. This kind of coal mill has the characteristics of low energy consumption and smooth output and has a small effect on abrasive wear and an

Contact

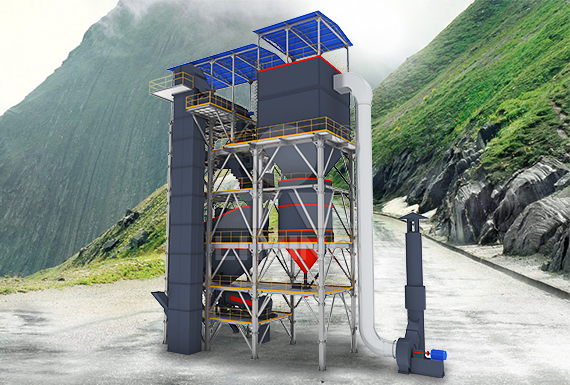

Coal mill, gypsum mill, clay mill, etc. Pfeiffer MPS mills

网页The grinding principle and the high efficiency classifier ensure the reduction of electric energy consumption by up to 40% as compared with conventional ball mills. MPS 200 BK coal mill, Krimzement Bakhchisarayski, Ukraine. MPS 3070 BK

Contact

Coal Mill Coal Fired Power Generation Shanghai Electric

网页2021年1月23日 Vertical Coal Mill On the basis of retaining the advantages of RP grinders, the innovative HP medium-speed coal grinder which absorbs the structural characteristics of MPS and MBF coal grinders has the advantages of various grinders. Its grinding parts have a long service life and are easy to replace. Ball Grinding Mill Dual inlet dual outlet steel

Contact

Vertical Coal Mill Power Generation Equipment Shanghai

网页2021年1月23日 Technical Advantages. Shanghai Electric Heavy Industry Group produces a range of basic products, such as metallurgic and rolling mill machinery, grinding equipment for power plants, miningcementing equipment, large-sized forgingpressing equipment and other heavy machinery. Our company was honored as Famous-brand Products in

Contact

ypes of coal mill mps high power grinders mill

网页Types Of Coal Mill Mps . Different Types Of Coal Mills Mps Coal Mill Specs Atafinch Mps coal mill specs. Mar 01 2009 Our experience with both RP andMPSpulverizers has been thatmillsdesigned for a throughput of about 120 000 pounds ofcoalper hour an HGI of about 45 to 50 andcoalfineness exceeding 75 . Send Email List Chat Online.

Contact