المنتجات الساخنة

Research on early fault warning system of coal mills based

网页2019年9月9日 In coal-fired power plants, the coal mill is the core equipment of the milling system. Failure of the coal mill during operation will directly affect the stability and

Contact

Coal Pulverization System: Explosion Prevention and

网页2017年1月5日 The raw coal is pulverized in the vertical cylindrical mill, and the pulverized coal is lifted to a powder separator by another bucket elevator. The powder separator

Contact

Coal Pulverizer Power Plant Pall Corporation

网页2 天之前 The four most common coal pulverizers types are: Ball-Tube Mills. This type of mill consists of a rotating tube filled with cast alloy balls. Coal is introduced through two

Contact

Early Warning of Critical Blockage in Coal Mills Based on

网页2020年9月25日 Coal mills have a significant influence on the reliability, efficiency, and safe operation of a coal-fired power plant. Coal blockage is one of the main reasons for coal

Contact

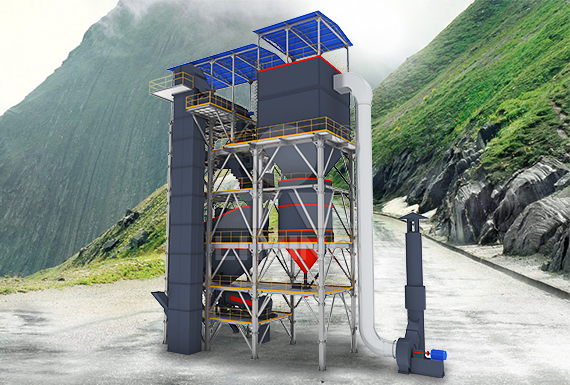

Coal mills for all requirements Gebr. Pfeiffer

网页Coal, lignite or petcoke are ground in the Pfeiffer vertical mill by using hot gases from a hot gas generator. The grinding plant can be inerted. The raw coal is dried while being

Contact

Effects of Sparking from Various Classes of Tool Steel in

网页The earliest recorded Ignitions attributed to Frictional Sparking were believed to be produced by sparks either from the blow of a hand pick on hard rock or from the sparks given off by

Contact

Milling Biomass / Coal AMETEK Land

网页Milling. The coal mill is a key ancillary to any pulverized fuel boiler. It grinds the coal to a fine powder so that it can be burned with maximum efficiency. Biomass also moves through

Contact

Boiler Mill and Coal Pulverizer Performance GE

网页2023年7月24日 YES. Our boiler mills and coal pulverizers span the globe and are built in a variety of sizes and capacities. We provide customized maintenance solutions, and offer a full spectrum of high-quality solutions

Contact

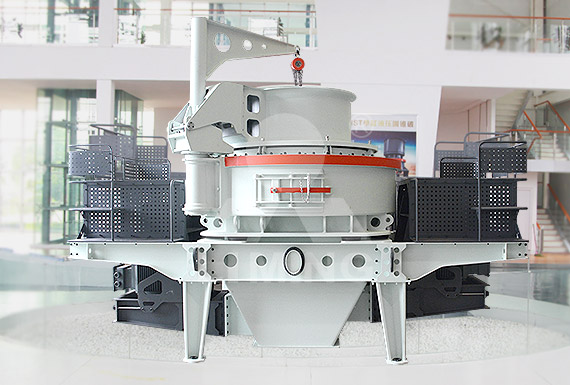

Vertical Coal Mill for Coal Grinding in Cement

网页Vertical Coal Mill. Feeding size: ≤110mm. Capacity: 5-70t/h. Motor power: 110-1400kW. Applications: Vertical coal mill is mainly used for grinding raw coal, bituminous coal, and other fuels into coal powder, which is supplied

Contact

Early Warning of Critical Blockage in Coal Mills Based on

网页2020年1月1日 Coal blockage is one of the main reasons for coal mill malfunction. It is highly essential to accurately detect the critical blockage in coal mills to ensure a safe and stable operation of the

Contact

reason for sparking in coal mill kwekerijmandragora

网页2019年11月11日 Pulverizer . 2021 10 8 Types of coal pulverizers Coal pulverizers may be classified by speed as follows Low Speed Medium Speed High Speed Low speed Ball and tube mills A ball mill is a pulverizer that consists of a horizontal rotating cylinder up to three diameters in length containing a charge of tumbling or cascading steel balls pebbles or rods

Contact

Pulverised Coal Flow measurement in Thermal Power

网页2018年12月12日 In this , GA is applied to develop the coal mill model and to estimate the pulverised coal flow using real time on-site plant data. 2. COAL MILL MODELLING. In thermal power plant, pulverization of coal is carried out by coal mill. Raw coal is moved from the storage to the mill by conveyor mechanism. The type of coal mill envisaged for our

Contact

Coal Pulverization System: Explosion Prevention and

网页2017年1月5日 The raw coal is pulverized in the vertical cylindrical mill, and the pulverized coal is lifted to a powder separator by another bucket elevator. The powder separator consists of a centrifugal rotor, 6 cyclones and a self-recycling pneumatic system. Large size particles return to the mill, and fine powder is collected by cyclones and then

Contact

(PDF) An investigation of performance characteristics and

网页2020年8月12日 VRM has been widely researched in processing of cement (Ito et al. 1997;Jorgensen 2005;Wang et al. 2009, Ghalandari et al. 2021), coal (Tontu 2020), iron ore (Reichert et al. 2015), zinc ore (van

Contact

Coal Pulverizer Power Plant Pall Corporation

网页2 天之前 The four most common coal pulverizers types are: Ball-Tube Mills. This type of mill consists of a rotating tube filled with cast alloy balls. Coal is introduced through two hollow trunnions on each side of the tube. As the tube rotates, the balls tumble onto the coal, crushing and pulverizing it. Impact Mills.

Contact

A Modeling and Optimizing Method for Electricity Current

网页2022年2月9日 Coal mills consume a huge amount of station service electricity power of a coal-fired power plant. Meanwhile, the operation of coal mills also has a large influence on boiler combustion. Among all the operating factors, the electricity current intensity of coal mills reflects the electricity power consumption as well as operating status of coal mills. If

Contact

reason for sparking in coal mill

网页reason blast in coal mill ofspescaracolli it. reason blast in coal mill vrystaatboranklubcoza coal mill explosion root causes gatewaypreschool A mill puff is an explosion in the mill system caused by an explosive combination of coal air and temperature Mill puffs most often causes of explosion in coal mill oceanmed Explosions in a pulverized coal system are

Contact

BHARAT HEAVY ELECTRICALS LIMITED

网页2017年2月7日 Pulverisation of coal by attrition and by impact of hard balls Speed reduction achieved by gear train consisting of reduction gear box and large spur gear. Coal can be fed and removed from both sides of the mill. Half mill operation for partial loads allowed. Input coal size 25 mm white output is 70 to 90 microns

Contact

A former mining camp is converting into a boutique getaway, sparking

网页2020年9月15日 And the sparks couldn’t come at a better time. Hope for a new uranium mill in the nearby Paradox Valley has died. The promise of a resurgence from the exploding hemp industry has not materialized. The local Tri-State power plant and coal mine closed two years earlier than planned.

Contact

Coal Mill in Cement Plant Vertical Roller MillAir-Swept Ball Mill

网页It is a mechanical device used to grind raw coal into pulverized coal powders. The most used coal mills in cement plants are air-swept ball mills and vertical roller mills. At present, most cement plants use coal as the main fuel in the clinker production process. The standard coal consumed by the new dry process for producing 1 ton of cement

Contact

Modeling of a medium speed coal mill ScienceDirect

网页2017年8月1日 Modeling of the coal mill. In this study, the lumped parameter modeling method is adopted with the following assumptions: 1) the parameters of the medium in the coal mill are uniform; 2) the media in the coal mill are incompressible; 3) the parameters of the medium in the coal mill change along the axial direction only; 4) the change in the

Contact

(PDF) Fault analysis and optimization technology of HP

网页2021年8月1日 3.10 The low lubricating oil pressur e of the coal mill caused the trip of the coal mill Cause analysis : ( 1 ) Insufficient output of oil pump. ( 2 ) The filter screen is seriously

Contact

Effects of Sparking from Various Classes of Tool Steel in

网页The earliest recorded Ignitions attributed to Frictional Sparking were believed to be produced by sparks either from the blow of a hand pick on hard rock or from the sparks given off by the steel mill and flint used at that time for underground illumination. The application of machinery to coal cutting has been progressively increasing during

Contact

Characteristics of Fly Ash from Thermal Power Plants and

网页2022年4月24日 precipitator, particularly coal mills, burners, and air pre heaters. The operation of coal burners, together with the setting of the coal mills and their classifiers, affects the percentage of unburned carbon(UBC) in the fly ash. The use of Lo NOx burners increases this percentage, and causes re-entrainment and increased sparking in the

Contact

Industrial Coal Pulverizer Model Simulation and Parametric

网页2018年1月1日 Mafezzoni (1996) described this developed model as more of a knowledge-based model than a control model. Control of coal mills up to a certain extent has been developed (Fan and Rees, 1994). A team from ABB designed a coal mill model for monitoring and control based on Fan and Rees principle using 3 particle size

Contact

Motor carbon brush sparking. Why it happens and how can I

网页2019年11月30日 The sparking should be mild and red/orange in colour, if blue and appears almost all around the comm, it can indicate a short circuit somewhere. The conclusive test for a armature, short etc, is an instrument called a Growler, measures voltage produced across each comm section when the armature is under test. Max.

Contact

Analysis of the Coal Milling Operations to the Boiler

网页2021年10月28日 From the coal yard, the coal is transfer to the mill bunkers through conveyor belt. The bunkers are sized for an effective capacity of twelve (12) hours at BMCR with design coal. Each mill bunker has one hopper, connected to the feeders. Mills operate when the bunker coal gate valves are opened, coal is allowed to flow to the gravimetric

Contact