المنتجات الساخنة

A systematic review of sustainable gold extraction from raw

网页2022年3月1日 Finally, using an electrowinning process, gold can be extracted in metallic form, capable of feeding the smelting stage, as shown in Fig. 2. The aim of this stone is

Contact

HYDROMETALLURGICAL PROCESSING OF GOLD

网页2021年6月2日 that the hydrometallurgical processing of raw materials is the most effective and economically profitable process of obtaining gold from ore [1–4]. Several

Contact

Operating Costs of Gold Processing Plant 911

网页2016年3月18日 The savings made in lower operation costs and lower maintenance costs are noticeable and this saving was also made in the face of a 12.5% increase in wages made when the new plant was started.

Contact

Summary of Gold Plants and Processes ScienceDirect

网页2016年1月1日 Summary of Gold Plants and Flow Sheets Discussed in Gold Ore Processing, Second Edition. Implemented with tube autoclaves 1.5 km long and 5 cm

Contact

Gold Ore Processing ScienceDirect

网页Gold Ore Processing: Project Development and Operations, Second Edition, brings together all the technical aspects relevant to modern gold ore processing, offering a practical

Contact

Gold Processing PlantsComplete Ore Process

网页1 天前 The chart/table below are crude budgetary estimations for the cost of major plant equipment. Actual cost will vary depending of the process details and detailed equipment list and origin. Please use this to decide if

Contact

How Does A CIP Gold Processing Plant Work?

网页2021年3月18日 The main process of the CIP gold processing plant to extract gold from ore and convert it into pure metal can be divided into 6 steps: crushing, screening, grinding, classification, carbon slurry gold

Contact

Production of Gold West Virginia University

网页2016年8月1日 A feasibility study on the production of gold at a fictitious mine (Moapa mine) in Elko County, Nevada is to be performed. The mine is capable of producing 325,800

Contact

Ultrafine Grinding an overview ScienceDirect Topics

网页G. Deschênes, in Gold Ore Processing (Second Edition), 2016 4.4 Ultrafine Pyrrhotite Concentrate. Ultrafine grinding is used to liberate gold finely disseminated in metallic sulfides. K is the first gold mine using ultrafine grinding followed by cyanidation (Ellis and Gao, 2002).The gold sulfide concentrate is grind with an IsaMill to a P 80 of 10–12 μm.

Contact

How Gold Is Mined Gold Mining Process World Gold Council

网页2 天之前 The gold mining operation stage represents the productive life of a gold mine, during which ore is extracted and processed into gold. Processing gold involves transforming rock and ore into a metallic alloy of substantial purity known as doré typically containing between 60-90% gold. During its life, a number of factors such as the

Contact

Gold Processing MethodsGold Ore Extraction

网页2015年9月15日 This page offers a comparative review of gold recovery methods: Flotation and Leaching of the Float Conc. Flotation and Leaching of the sulfide-free Float Tails. Gravity Gold Concentration followed by

Contact

How Does A CIP Gold Processing Plant Work? Mining-pedia

网页2021年3月18日 The main process of the CIP gold processing plant to extract gold from ore and convert it into pure metal can be divided into 6 steps: crushing, screening, grinding, classification, carbon slurry gold extraction and tailings treatment. (CIP gold processing plant diagram) #1. Crushing. The raw gold ore transported to the CIP gold beneficiation

Contact

Gold Processing Plant Prominer (Shanghai) Mining

网页Gold ore. Prominer maintains a team of senior gold processing engineers with expertise and global experience. These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc., to achieve the processing plant of optimal and

Contact

Summary of Gold Extraction Process cnlitereagent

网页2019年8月22日 1. Flotation Gold Extraction Process Principle. Flotation gold extraction process is based on the difference of physical and chemical properties of the ore surface, and is processed by flotation reagent to make the useful mineral adhere to the bubble to achieve the purpose of gold extraction.. Gold is an easy-floating mineral, so flotation gold

Contact

Extracting gold: the basics, the methods and the technology

网页2023年7月24日 The 3 phases of gold processing. Gold processing generally occurs in three phases: extracting gold from the ground, refining, and manufacturing. Extracting gold begins in open-pit or underground mining. Then, the gold is separated from the gold-bearing rock with chemical processes involving toxic substances like cyanide leaching, zinc dust,

Contact

Gold Processing Plant Multotec

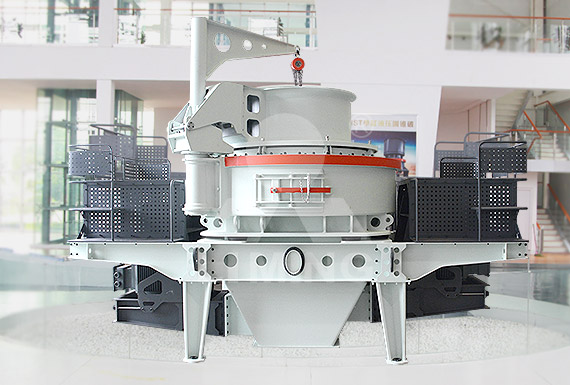

网页The typical gold processing plant begins with a cone crusher, to reduce the particle size of the ore. Next, it is loaded on a conveyor belt, where an overbelt magnet removes tramp metal from the gold mining process. The ore goes for preliminary screening, followed by stream sampling, which is a process that uses a hammer sampler. A semi

Contact

Gold Ore Importers In India Suppliers, all Quality Gold Ore

网页Flotation Machine(ISO9001-2008) widely uesd in gold ore beneficiation production plant from top brand manufacturer in China. stone grinding plant pk gold processing ore ball mill 80 mesh. Country/Region: China. JOYAL milling equipment Gold ore Grinding Plant Gold Ore Processing Plant Cost. Country/Region: China.

Contact

CIL gold processing plant CIL processing plant for sale

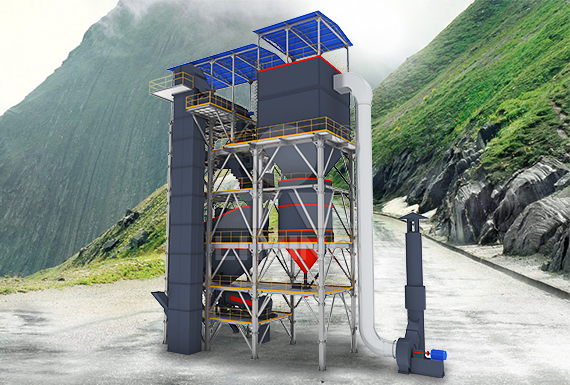

网页CIL gold processing plant mainly consists of following steps: 1 The ore is first reduced in size (typically 90% passing 200mesh ) to ensure that all non-refractory gold is readily accessible for cyanide leaching, There are several variations of comminution circuits used in the gold leaching industry, such as: Multi-stage crushing, then ball milling circuits, typical of ball

Contact

Gold processing 101 Mining Magazine

网页2017年9月7日 At current gold prices this is worth about US$600. Both smelter treatment charges and oxidation or bio-leach costs are at least $200/t of concentrate and payables/recovery in the 90% range, so a minimum GSR for effective downstream processing is around 0.5. Clearly this is a function of gold price, but in the current gold

Contact

Gold extraction QueensMineDesignWiki

网页2019年6月28日 The costs associated with power supply, grinding media, and liners used in comminution circuits almost always represent the single largest cost in gold extraction processes (Mosher, 2005). Thus, the

Contact

(PDF) Grinding in Ball Mills: Modeling and Process

网页2012年6月1日 A ball mill is a type of grinder widely utilized in the process of mechanochemical catalytic degradation. It consists of one or more rotating cylinders partially filled with grinding balls (made

Contact

Ore Processing OceanaGold Waihi Operation Waihi Gold

网页2023年7月24日 Ore processing is a 24 hour operation. Ore is stockpiled at the processing plant, and the process begins by feeding the ore into a hopper with a loader. The ore is conveyed, and lime is added to raise its pH. Following crushing through a jaw crusher, the ore is fed into the semi autogenous grinding (SAG) mill along with water and steel balls.

Contact

Comminution Circuits for Gold Ore Processing ScienceDirect

网页2016年1月1日 3. Mining Factors. The size reduction process starts with mining, and the degree of fracturing and breakage achieved in drill and blast is an important factor in comminution circuit performance. Correspondingly, the selected mining process is a consideration in development of the comminution circuit design.

Contact

ETALLURGICAL PROCESS D PLANT ESIGN AusIMM

网页2021年6月24日 design. The requirement for campaign processing or blending of ore types should be considered. In the case of Kanowna Belle, soft oxide ore encountered early in the life of the mine allowed a staged plant design. The Stage 1 plant consisted of a relatively low capital cost plant with the ability

Contact

Lime use in gold processing A review ScienceDirect

网页2021年12月1日 The main lime consuming reactions that, in combination, contribute to the overall lime consumption of gold processing plants, are briefly discussed: Magnesium pH buffering Magnesium is an abundant element contained in gangue ore minerals (Chryssoulis and McMullen, 2016) and in process solutions. Magnesium is solubilized at

Contact

Iron Ore Processing,Crushing,Grinding Plant Machine

网页1. Magnetite ore stage grinding-magnetic separation process The stage grinding-magnetic separation process mainly utilizes the characteristics of magnetite that can be enriched under coarse grinding conditions, and at the same time, it can discharge the characteristics of single gangue, reducing the amount of grinding in the next stage.

Contact

5 Gold Extraction Methods to Improve Your Recovery Rate

网页2020年5月8日 The gold ore grinding equipment in the grinding stage: ball mill,rod mill. Ⅲ. Beneficiation stage The beneficiation stage is a crucial part of gold extraction during the whole gold ore processing plant. Placer gold mine and rock gold mine are most widely processed to extract gold concentration.

Contact

10 Best Ore Beneficiation Plants for Sale (with Costs)

网页2021年3月24日 38%. Recovery rate. 74%. Manganese beneficiation machines: GZD-850×3000 vibrating feeder,PE-500×750 jaw crusher,Φ1200 cone crusher,B500x10 m belt conveyor, 2YK1535 inclined vibrating screen,Ф2700×4500 ball mill, High-strength Magnetic drum separators. 07 150 TPH Bauxite ore beneficiation plant in Indonesia.

Contact