المنتجات الساخنة

Pre-concentration of nickel in laterite ores using physical separation

网页2019年9月1日 The chemical assays of the laterite samples are provided in Table 2. The nickel head grade of ores L, I and S (at <300 μm size fraction) was found to be 1.2%,

Contact

Comprehensive Review on Metallurgical Upgradation Processes of Nickel

网页2022年2月11日 With the vigorously growing demand of the steel industry, corrosion resistance alloys, clean energy industries, and a variety of engineered infrastructure or

Contact

Separation and recovery of iron and nickel from low-grade

网页2020年11月1日 The magnetic separation efficiency of nickel from the laterite ore was evaluated using the recovery ratio of nickel R ni using the formula: (1) R Ni = m Ni × β Ni

Contact

Preconcentration strategies in the processing of nickel

网页2015年8月1日 For fine ore (0.315–0.2 mm) a feed assaying 1.42% Ni was upgraded to 2.20% Ni in 50% of the initial mass for a Ni recovery of 77.5%. Dense medium separation

Contact

Efficient enrichment of nickel and iron in laterite nickel ore

网页2020年3月1日 The process of deep reduction and magnetic separation was proposed to enrich nickel and iron from laterite nickel ores. Results show that nickel–iron

Contact

Direct Extraction of Nickel and Copper from Low-Grade Nickel

网页2022年1月18日 The low-grade nickel sulfide ore used in this research is derived from the Jinchuan nickel ore, China. After crushing and grinding, the ore powders were divided

Contact

Pre-concentration of nickel in laterite ores using physical separation

网页2019年9月1日 Laterites are generally processed through hydro or pyro-metallurgy and therefore, pre-concentration of nickel before such processes is very important. This

Contact

Nickel processing Extraction, Refining, Alloying

网页nickel processing Nickel processing Extraction, Refining, Alloying: The extraction of nickel from ore follows much the same route as copper, and indeed, in a number of cases, similar processes and equipment are

Contact

Separation and Recovery of Iron and Nickel from Low-Grade

网页2018年10月1日 The low-grade nickel laterite ore used in this study was successfully upgraded through selective reduction by industrialized rotary kilns followed by magnetic

Contact

Extraction of Nickel from Oxidized Nickel Ores by Heap

网页2022年9月28日 A characteristic feature of serpentine oxidized nickel ores (ONO) of the Serov deposit (≈ 1 wt.% Ni) is the increased content of iron and magnesium. The main

Contact

Magnetic separation for mining industry

网页Global Fourth-generation Vertical Ring High Gradient Magnetic separator (Oil-water complound cooling) Application: This type of magnetic separation machine is used in wet separation processes for smaller than 1,2 mm (

Contact

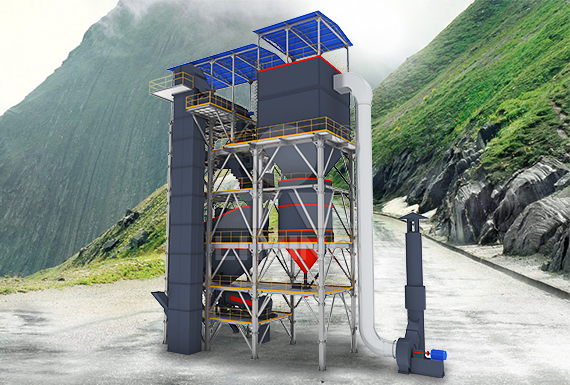

Nickel Ore Mining Process Equipment Flow Cases JXSC

网页2 天之前 Nickel (element #28, symbol Ni) is a silvery shiny, metallic element. It can be hammered into thin sheets, which means it is malleable. Nickel was discovered in 1751 by Axel Fredrik Cronstedt. Iron, cobalt and nickel (numbers 26, 27 and 28 on the Periodic Table) are the only three elements known to be ferromagnetic (the strongest type of

Contact

Advanced study on the extraction of Nickel from its ores

网页2023年6月26日 saprolite. The ore is dried and nickel is selectively reduced (together with cobalt and some iron) to metallic nickel at ~ 700°C. The metallics are extracted by leaching in an ammoniacal solution. Recovery of nickel and cobalt decreases with the increasing amount of saprolite since nickel and cobalt are locked in a silicate matrix and are

Contact

Find A Wholesale nickel flotation separator Online

网页Alibaba is the place to look for nickel flotation separator tools, with options for ore extraction, precious metal mining and much more. MENU MENU Alibaba High Quality 500TPH Mineral Processing Plant Zambia South Africa XJK SF Type Flotation Cells Nickel Ore Flotation Separator $1,400.00 $1,680.00.

Contact

Extraction of Nickel from Garnierite Laterite Ore Using

网页2020年4月15日 In this study, segregation roasting and magnetic separation are used to extract nickel from a garnierite laterite ore. The garnierite laterite ore containing 0.72% Ni, 0.029% Co, 8.65% Fe, 29.66% MgO, and 37.86% SiO2 was collected in the Mojiang area of China. Garnierite was the Ni-bearing mineral; the other main minerals were potash

Contact

Pre-concentration of nickel in laterite ores using physical separation

网页2019年9月1日 The chemical assays of the laterite samples are provided in Table 2. The nickel head grade of ores L, I and S (at <300 μm size fraction) was found to be 1.2%, 1.1%, and 3.0%, respectively. Nickel was found, more or less, at the same grade in all size fractions in these laterite ore samples.

Contact

Find A Wholesale nickel ore magnetic separation Online

网页Nickel Ore Magnetic Separation (15 products available) 1/4. Nickel ore separation magnetic separator for nickel ore and spodumene ore / set. 1 set (Min Order) CN Shicheng County Jinchuan Mineral Equipment Manufacturing Co., Ltd. 10YRS. 3.0

Contact

Separators for nickel metal hydride and nickel cadmium

网页2004年10月29日 Consequently, polyamide separators are mostly used in nickel–cadmium (NiCd) cells. Polyolefine-based materials have to be post-treated to obtain a hydrophilic surface. Additionally, homogeneity of the material has to be as good as possible to avoid electrical shorts inside the battery, especially after high numbers of storage/discharge

Contact

镍矿石 (Nickel Ore) [EE]Emendatus Enigmatica MC百科

网页镍矿石 (Nickel Ore)资料的介绍页面,此资料来自模组[EE]Emendatus Enigmatica,我的世界MOD百科,提供Minecraft(我的世界)MOD(模组)物品资料介绍教程攻略和MOD下载。

Contact

Extraction of Nickel from Garnierite Laterite Ore Using

网页2020年4月15日 In this study, segregation roasting and magnetic separation are used to extract nickel from a garnierite laterite ore. The garnierite laterite ore containing 0.72% Ni, 0.029% Co, 8.65% Fe, 29.66% MgO, and 37.86% SiO2 was collected in the Mojiang area of China. Garnierite was the Ni-bearing mineral; the other main minerals were potash

Contact

How to Extract Nickel from Ore? Mining Pedia

网页2022年4月21日 1. Sulphide Copper Nickel Processing. 2. Nickel Oxide Processing. To Wrap Up. Nickel ore is mainly divided into sulfide copper-nickel ore and nickel oxide ore (laterite nickel ore), and the beneficiation and processing methods of the two are completely different. The world's proven basic nickel reserves are about 69 million tons, and the total

Contact

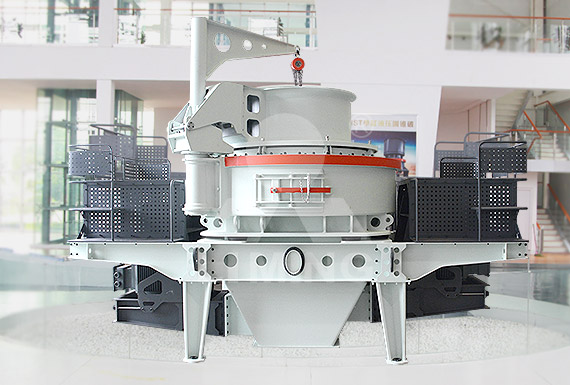

nickel ore processing plant, nickel ore

网页Copper- Nickel Ore Flotation Process When process copper-sulfide nickel ore, collector and frother will be used in order to better results. A basic principle of copper-sulfide nickel ore process is that it is better to let

Contact

(PDF) Advanced Review on Extraction of Nickel from Primary

网页2019年1月10日 Processing options for various types of nickel ore and their products (Adapted from Crundwell et al., 2011). High-pressure acid leaching (HPAL) process flowsheet operating at Moa Bay (Adapted from

Contact

SmallMedium Scale Mining Expert, Equipment

网页2 天之前 Magnetic separators are widely used in the beneficiation of ferrous metal ores, non-ferrous and rare metal ores; the recovery and purification of media in heavy media beneficiation; the removal of impurities from non-metallic ore raw materials; the removal of iron-containing impurities in crushing; recycling scrap steel from smelting waste residue

Contact

Mineral Washing Plant Nickel Ore Spiral Chute Separator

网页2023年7月8日 Ore and sand can be divided under rotary steam and centrifugal force according to the slurry's different specific gravity, grain size and shape. 4) Next, final ore flows to the final ore hopper and coveyed out by pipe and picked up, and final sand flows to final sand hopper and coveyed out by pipe to sand pond. Then remove the sand pump.

Contact

Types of Mining Magnetic Separators Mineral Processing

网页2020年7月10日 The sizes of magnetic separators with three types of troughs are as follows: downstream troughs ≤6 mm, reverse troughs ≤1.5 mm, and semi-reverse troughs ≤0.5 mm. The downstream magnetic separator has a large processing capacity and is suitable for the rough separation and cleaning of the stronger magnetic materials with a

Contact

Magnetic Separators Multotec

网页Magnetic Separators. Multotec supplies a complete range of magnetic separation equipment that effectively separates ferromagnetic and paramagnetic particles from dry solids or slurries. Magnetic separators are renowned for their separation of magnetic ore; they can also serve as an electromagnet effective for removing tramp metals

Contact

How to Extract Nickel From Copper-Nickel Sulfide Ore?

网页2020年1月7日 Here are four processes used in the froth flotation process of copper-nickel sulfide ore. 1. Differential flotation or partial differential flotation process. When the content of copper is much more than nickel in the ore, this process can be used to separate the copper as the single concentrate. The advantage of this process is that the copper

Contact

Pre-concentration of nickel in laterite ores using physical separation

网页2019年9月1日 Laterites are generally processed through hydro or pyro-metallurgy and therefore, pre-concentration of nickel before such processes is very important. This stone examines the effects of different physical methods on pre-concentration of nickel in laterite ores. The effect of ore mineralogy on choosing the best strategy to upgrade nickel will be

Contact