المنتجات الساخنة

Stone Crushers: A Technical Review on Significant Part of

网页2022年5月14日 2 Concept of Stone Crusher. Stone Crusher is a sort of pulverizer which is utilized to compress or break out assortment of enormous stones. It normally highlights a huge crushing rate and high return and is utilized as an essential equipment in primary,

Contact

Everything you need to know about Crushers in Cement industry

网页2017年6月24日 The hammer crusher is the most widely used machine for the primary reduction of the cement industry. The main feature is the rotor, which carries a series of

Contact

Complete Lecture about Crushers in Cement Industry

网页Fig. 3.22. shows the arrangement of a double roller crusher, and Fig. 3.23. represents a triple roller crusher. Frequently the cement industry also employs roller crushers for the

Contact

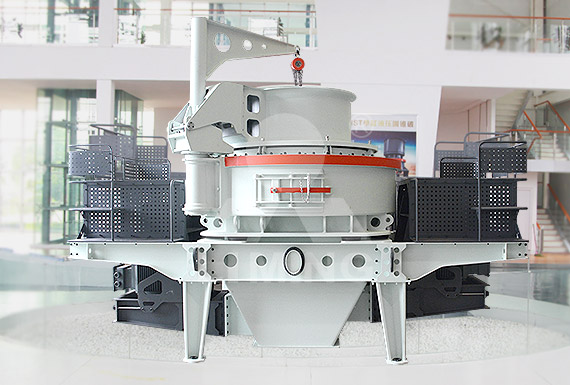

Cement Crusher Crusher In Cement Plant

网页Raw materials of the cement plant are mostly from open-pit mines, and the ore size of large mines can reach 1.5-1.8m. In the preparation of cement raw materials, we first need to crush limestone, gypsum, clay and other

Contact

Cement Crusher Crushers for Cement Plant

网页Cement Manufacturing Equipment. Cement Crusher. Crusher is a kind of machinery that is widely used in the cement production industry. It is

Contact

The Major Role of Crusher and Grinder Mill in Cement Industry

网页The major role of crusher and grinder mill in cement industry As technology developed, broken machinery technology updates, its scope more widely, not only for use in mineral

Contact

Function Of Crusher In Portland Cement Making Crusher

网页In cement mining,cement grinding mill and cement crusher play a very important role. They can crush or grind the cment to required fineness for industry application. Portland

Contact

What is the role of impact crusher in cement industry?

网页2021年5月10日 Impact crusher as a important equipment in the system of sand production line, applies not only to very hard materials, is more applied to the material performance

Contact

THE CRUSHER IN CEMENT INDUSTRY Crusher Mills, Cone Crusher

网页liming jaw crusher used the slag in cement industry CNC . The cement industry in raw materials, a lot of use cinder power gypsum, blast furnace slag and other industrial

Contact

Why is a crusher section used in the cement industry?

网页2023年3月1日 A crusher section is used in the cement industry to reduce the size of raw materials such as limestone, clay, and other materials. The crushed material is then used

Contact

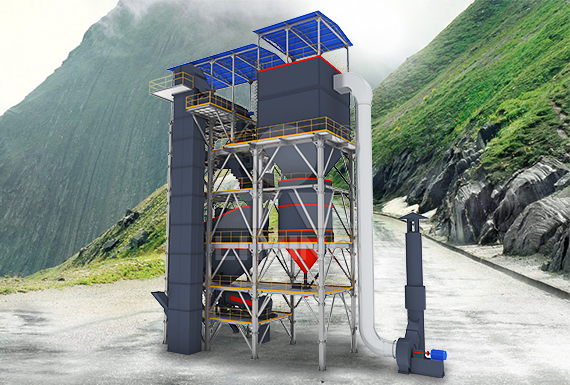

Cyclone preheater in cement plant

网页The cyclone preheater, also called cement preheater, suspension preheater, is a kind of preheater in cement plant.As the core equipment of dry method cement production line, cyclone preheater use suspension preheating to preheat and partly decompose the cement raw mix, shorten the length of the rotary kiln, fully mix raw mix and hot air in the kiln,

Contact

Function Of Crusher In Portland Cement Making Crusher

网页In cement mining,cement grinding mill and cement crusher play a very important role. They can crush or grind the cment to required fineness for industry application. Portland Cement Crusher,Portland Cement Clinker Grinder Unit

Contact

Report on Cement manufacturing process PDF

网页2016年7月7日 The capacity of Jaw Crusher is 130 tons per hour Hammer crusher: Hammer crusher is a kind of machine widely used in crushing medium hardness materials such as Limestone, slag, coke and coal in

Contact

Cement Plant Cyclone Preheater

网页AGICO Cement Preheater Features. Our cyclone preheater adopts a multi-stage circulation suspension preheating mode, and has a high production efficiency. The preheating temperature in the cyclone preheater can reach 900℃; The most part of the cyclone preheater is made of refractory material, which is heat resistant and has long service life;

Contact

||Volume 9, Issue 4, April 2020|| Concrete MIX DESIGN

网页2020年11月30日 2 Type of Cement PSC Conforming to IS: 455- 1989 3 Maximum Nominal Size of Aggregate 20mm 4 Minimum Cement Content 300 kg/ m3 (As per IS: 456- 2000) 330 kg/ m3 (As per Dastur Technical Specification) 5 Maximum Water Cement Ratio- 0.50 (Asper IS:456- 2000) 6 Degree of Workability Slump required 150 mm 7

Contact

Integrated energy optimisation for the cement industry: A

网页2014年2月1日 The combined electrical energy consumption of grinding systems can constitute up to 75% of all energy used in the cement industry [2], [12]. This corresponds to a total production cost component of 50–60% for energy of which 17.8–42.6% is allocated to electricity alone [2]. The fairly large variation is attributed to different pricing

Contact

Modeling of energy consumption factors for an industrial cement

网页2022年5月9日 Cement production is one of the most energy-intensive manufacturing industries, and the milling circuit of cement plants consumes around 4% of a year's global electrical energy production. It is

Contact

Clinker Cooler Cement Cooler AGICO Cooler In Cement

网页In the calcination process of cement clinker, preheating, calcining, and cooling are three inseparable process links. As the supporting equipment of cement rotary kiln, clinker cooler (also called cement cooler) is a kind of heat exchange device that transfers heat from high-temperature clinker to low-temperature gas.It plays an important role in the cement

Contact

Everything you need to know about Crushers in Cement industry

网页The hammer crusher is the most widely used machine for the primary reduction of the cement industry. The main feature is the rotor, which carries a series of pivoted hammers. When the rotor is running, the centrifugal forces cause the

Contact

Clinkerization Cement Plant Optimization

网页The liquid percentage at 1450 0 C can be estimated using the formula. % Liquid content (1450 0C) = 3.0 x A+2.25 x F+S. Where A=Al 2 O, F=Fe 2 O 3, S= MgO+K 2 O+Na 2 O+SO 3 In Clinker. The normal range of liquid phase is 22-27%. Burnability is a reference value for raw meal indicating how difficult it is to burn.

Contact

Disclaimer Green Business Centre

网页2022年2月28日 Energy Benchmarking for Cement Industry 3 CHAPTER-1 INTRODUCTION 1.0 Indian Cement Industry Present Scenario India’s cement industry plays a vital role in the growth and development of the nation. The cement industry has been expanding with increasing infrastructure activities and demand from residential buildings

Contact

Cement Crusher Crusher In Cement Plant

网页Raw materials of the cement plant are mostly from open-pit mines, and the ore size of large mines can reach 1.5-1.8m. In the preparation of cement raw materials, we first need to crush limestone, gypsum, clay and other

Contact

Complete Lecture about Crushers in Cement Industry

网页Fig. 3.22. shows the arrangement of a double roller crusher, and Fig. 3.23. represents a triple roller crusher. Frequently the cement industry also employs roller crushers for the size reduction of coal, used as fuel in rotary drum driers. Capacity. The throughput capacity of a roller crusher can be determined using the following formula:

Contact

THE USE OF WASTE GLASS AS FINE AGGREGATE REPLACEMENT IN CONCRETE BLOCK

网页2011年6月1日 Similarly, Malek et al. [26] obtained up to 34.3% with the addition of waste glass as substitute for conventional fine aggregate. The increase in compressive strength of concrete could be

Contact

Review on vertical roller mill in cement industryits

网页2021年1月1日 India is the world's second largest producer of cement and produces more than 8 per cent of global capacity. Due to the rapidly growing demand in various sectors such as defense, housing, commercial and industrial construction, government initiative such as smart citiesPMAY, cement production in India is expected to touch 550–600 million

Contact

How To Choose Cement Crusher? Jaw Crusher, Cone Crusher

网页2019年10月30日 The cement crushing process. The raw material can be broken by extrusion, shearing, rolling or impacting. The crusher works by a single or a group of them. There are jaw crusher, gyratory crusher and cone crusher which work by extrusion principle. Hammer crusher and impact crusher working on impact principle.

Contact

Role In Limestone In Cement Grinding Crusher Mills

网页limestone crusher or limestone hammer crusher play,jaw crusher,impact crusher an important role in 08-31-2011 liming Limestone Crusher; 08-29-2011 Cement Grinding grinding process in cement This page is provide professional grinding process in cement

Contact

Final project Report on cement industry SlideShare

网页2018年5月28日 The cement industry of Pakistan was once a very small industry but it rapidly grew with the passage of time and finally it entered in the export market. The cement industry contributes in the Gross Domestic Product (GDP), it creates employment opportunities for thousands of people and it creates huge revenue for the government in

Contact

The Ultimate Guide to Concrete 3D Printing 3DSourced

网页2023年7月17日 The swift advancement of the 3D printed construction industry forecasts a market valuation of $1,575 million by 2024, from a mere $3 million in 2019. A driving factor behind this growth is the game-changing technology of concrete 3D printing (C3DP). C3DP, the dominant form of 3D printing in construction, revolutionizes the construction process.

Contact

Electrostatic Precipitator in Cement Plant ESP Dust Collector

网页Electrostatic Precipitator. Product Name: Electrostatic precipitator / ESP in cement plants. Dust Collecting Rate: ≥99.5. Weight: 4500 ~ 6900 kg. Equipment Resistance: ﹤ 400 Pa. Air Volume: 2460 ~ 11000 m 3 /h. Condition: Brand new. SEND INQUIRY. Electrostatic precipitators (ESP) are industrial gas cleaning devices that could remove dusts

Contact