المنتجات الساخنة

Current Status of Copper-Ore Processing: A Review

网页2021年9月8日 The choice of copper-ore processing technology depends on its composition, i.e., the sulfide, oxide, carbonate, and copper silicate content. Leaders in copper ore processing include Chile, Peru, the United States, Australia, China, Russia,

Contact

Copper Ore an overview ScienceDirect Topics

网页Flotation is preceded by crushing and grinding the mined Cu ore to small (∼100 μm diameter) particles. Its use has led to adoption of smelting processes that efficiently smelt

Contact

Copper processing Ores, Refining, Smelting

网页Principal forms in which copper ores are found include native copper, porphyry copper, massive deposits, and mixed ores. Native copper is simply the metal found unadulterated in nature. Occasionally copper is still

Contact

Copper Mining and Processing: Processing Copper

网页1 天前 This process uses a series of physical steps and high temperatures to extract and purify copper from copper sulfide ores, in four basic steps:

Contact

Copper Mining and Processing: Everything you Need to Know

网页The Basics of Copper Mining and Processing. Mined from open pits, copper ore must be crushed as part of the process that occurs between extraction and production. Using

Contact

A Guide To Copper Production and Manufacturing

网页2022年12月23日 The ore is then crushed and heated to separate the copper from other elements. This process is known as smelting and produces molten matte or blister copper, which is then refined further into

Contact

How to Process Copper Ore: Beneficiation

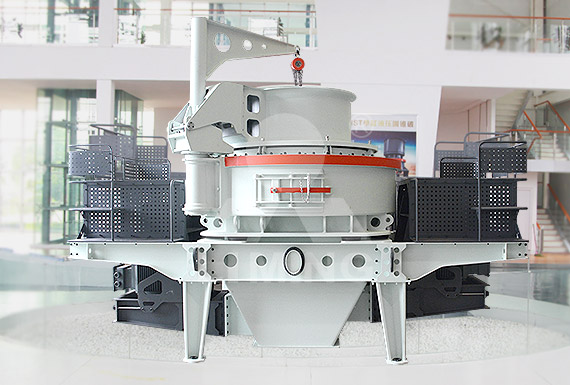

网页2023年3月13日 Before the beneficiation of copper ores, crushing and grinding are required. The bulk ores are crushed to about 12cm by a jaw crusher or a cone crusher. Then the crushed materials are sent to the

Contact

Crushing and grinding process of copper ore Crusher Plant

网页2022年6月6日 The coarsely crushed copper ore is screened by a vibrating screen, and then sent to a single-cylinder hydraulic cone crusher (medium crushing) by a belt

Contact

Copper Ore Crushing and Grinding Process CSDN博客

网页2012年10月18日 After crushing process, the copper ore is send to ball mill for grinding. Within the ball mill, the crushed copper ore will grind the ore to about 0.2 mm with 3-inch

Contact

How to Process Copper Ore: Beneficiation

网页2023年3月13日 Before the beneficiation of copper ores, crushing and grinding are required. The bulk ores are crushed to about 12cm by a jaw crusher or a cone crusher. Then the crushed materials are sent to the

Contact

Copper Ore Production Process JXSC Mineral

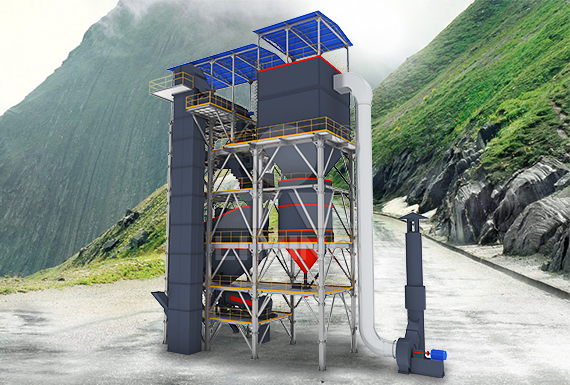

网页2023年5月6日 Copper Ore Production Process. May 6, 2023. The production process of copper ore processing mainly includes crushing, ore grinding, flotation, purification, and drying. The copper ore that needs to be processed must first go through the crushing process. The vibrating feeder is fed through the silo, and the vibrating feeder is evenly

Contact

Preferential sequence crushing of copper ore based upon

网页2019年1月15日 In this study, high voltage pulse breakage was used to study the breakage process of copper ore.The particle size, shape coefficient and preferential crushing index (Δ α i) were determined using systematic experiments.The parameters were further investigated by fitting the energy consumption model of breakage to the experimental data.

Contact

The six main steps of iron ore processing Multotec

网页Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency.

Contact

Processes and Equipment Used in the Copper Mining Process Mining

网页2019年11月27日 Besides, wet-process copper extraction process is also an effective copper mining process. 1. Crushing and Screening Stage. Using the crusher to break the copper ore to a certain particle size, which meets the requirements of feeding size in grinding stage. The common crushing stage of copper mining process includes three

Contact

Copper Ore Crushing SHANGHAI SANME MINING

网页2023年2月11日 SANME exported a cone crusher whose capacity is about 1500 t/h to a mining group ranking at the third place on scale in the world. Technological Process of Copper Ore Dressing. SANME SMS3000 Fully Hydraulic Cone Crusher is Delivered to Korea. SANME SDY 2100D Cone Crusher Being Delivered to Kazakhstan in 2014.

Contact

copper ore crushing-MINERAL PROCESSING-Crusher,Cone

网页SANME, as a famous supplier of mining crushing solutions, can offer complete set of copper ore crushing equipment and comprehensive technical support to every customer. COPPER ORE CRUSHING PROCESS. 1. According to the kind and characteristic of ore, there are many different processes for copper ore dressing. In general, ore dressing plant may

Contact

Copper Ore Processing ATAIRAC ENGINEERED PRODUCTS

网页2021年8月4日 Copper Ore Processing. According to the normal ore beneficiation process, copper ore processing is divided into crushing grinding grading floating –high grade copper ore tailing disposal. Crushing machine: Normally the ore dressing plant that the crushing scale is above medium size adopts three or four stages crushing process.

Contact

Copper crusher MiningQuarry Plant mining-crushing

网页2013年9月10日 The Copper Crusher is a geometric hammer found in the Nightfall campaign as well as the Eye of the North expansion. Acquisition Core. Zaishen Chest. Get price and support, find the working site in your country ! Please enter your demand such as production capacity, feeding material size, final product size.

Contact

Copper Mining and Processing: Everything you Need to Know

网页The Basics of Copper Mining and Processing. Mined from open pits, copper ore must be crushed as part of the process that occurs between extraction and production. Using today’s compact mining equipment, copper ore is extracted from the mine. After the ore is crushed, it’s roasted, which helps to convert sulfides to oxides.

Contact

Copper Production: How Is Copper Made? ThoughtCo

网页2019年9月26日 Sulfide Copper Ores . Virtually all sulfide-type copper ores, including chalcocite (Cu 2 S), chalcopyrite (CuFeS 2) and covellite (CuS), are treated by smelting.After crushing the ore to a fine powder, it is concentrated by froth flotation, which requires mixing the powdered ore with reagents that combine with the copper to make it

Contact

Copper Ore Processing Plants, Flow And Equipment

网页2020年7月10日 After the coarse crushed copper ore is screened, it is sent to the cone crusher by the belt conveyor for intermediate crushing and fine crushing, and the ore is broken into smaller ore particles. 2. Grinding process The copper ore processed into granules is screened by a vibrating sieve and sent to a ball mill for grinding and crushing.

Contact

extraction of copper, copper processing, copper extraction, copper

网页Copper Ore Benefication Process: 1.Large raw copper ore for primary crushing are fed into the jaw crusher by Plate feeder and are reduced to 8 inches or smaller. After first crushing, the material will transferred to cone crusher by belt conveyor for secondary crushing; the crushed copper ore stone will then transferred to vibrating screen for

Contact

Copper Ore Crushing, GrindingFlotation 911 Metallurgist

网页2017年5月21日 Grinding and Flotation. Fine ore at minus 19mm (¾”) sizing is fed at a controlled rate into the open-circuit 2600mm x 3960mm (8’-6 x 13’-0) Hardinge rod mill at an average feed rate of 2,106 STPD or 87.75 STRH. Rod mill discharge at a nominal size of minus 16 mesh and a pulp density of 75 percent solids combines with ball mill discharge

Contact

Crushing and grinding process of copper ore Crusher Plant

网页2022年6月6日 The coarsely crushed copper ore is screened by a vibrating screen, and then sent to a single-cylinder hydraulic cone crusher (medium crushing) by a belt conveyor for medium and fine crushing. Cone crusher is widely used in the medium and fine crushing process of iron ore, copper ore, gold ore and other metal mines.

Contact

Copper Ore Crushing and Grinding Process CSDN博客

网页2012年10月18日 After crushing process, the copper ore is send to ball mill for grinding. Within the ball mill, the crushed copper ore will grind the ore to about 0.2 mm with 3-inch steel balls. This copper ore slurry is finally pumped for the flotation deck.

Contact